Probe

Manufacturing precision and pace for engineering projects

Much more than a manufacturer, Probe is a supply chain partner for engineering projects; using their best-in-class products and services, responsive approach and know-how to accelerate delivery and increase overall equipment effectiveness.

Probe’s essence is encapsulated in how they deliver ‘engineering momentum’ and has an unrivalled knowledge and 40 years+ experience of delivering class-leading products and engineering expertise across three key service areas: manufacture requirements; manufacture, assembly and test; refurbs and upgrades. We are acutely aware of the demands and deadlines placed on our clients which is why we are fully equipped to deliver quickly, without compromising quality, to enable projects to progress as planned. Probe’s promise to you is always to find a solution to your engineering requirements whilst delivering momentum to your project.

The manufacture core service area from Probe includes a vast and growing offering of products, which are essential to both onshore and offshore oilfield operations. With the in-house capability to assemble and test full systems, Probe manufactures the individual components for all the systems offered, whilst providing full equipment packages where required. Capabilities also extend to provide a complete aftermarket service for customers’ assets ranging from full in-house refurbishment, upgrade and recertification, even if equipment wasn’t originally purchased from Probe.

Plant facilities

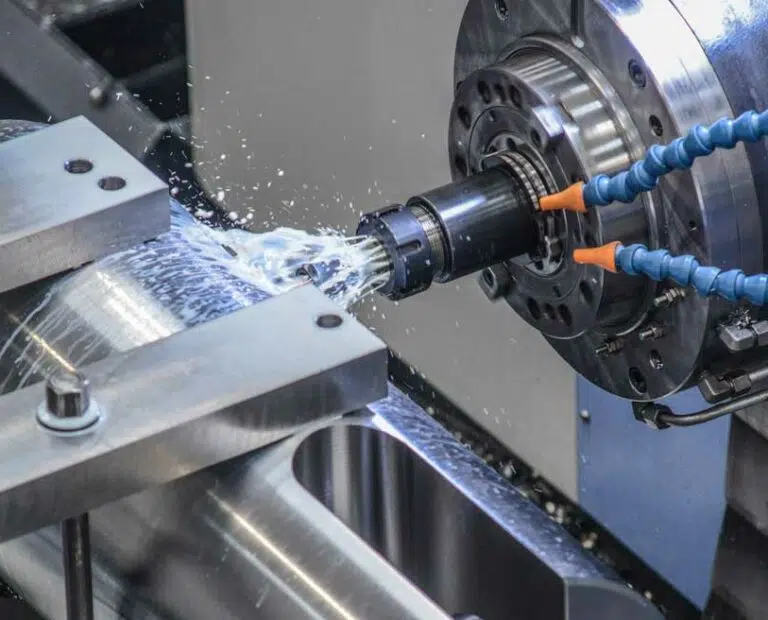

Working from a purpose-built machine facility consisting of over 50,000 square feet and equipped with some of the latest state-of-the-art and largest machine tools operated by time served engineers, Probe can design and manufacture oilfield equipment of the highest quality in the shortest possible time.

Our machining capabilities provide total flexibility to develop components of any size and specification across batch production and one-off items, either new IP or to customers’ IP. Over recent years we have invested £1.8 million in new machine tools. Our CNC plant includes high specification Mazak machinery and our welding bays boast automated T.I.G welding plant and a computer-controlled furnace.

Machining centres

The existing machine capacity in this section was doubled back in 2015 to coincide with the move to our new premises, following an investment of over £1.8 million in new machine tools.

Heritage

Probe has grown significantly over the years to respond to our client’s operating needs and we have built an enviable reputation and a robust suite of products and services. We are proud of our East of England roots and the fact that we can extend our services globally. Our offer has been strengthened further by becoming an Acteon Company, meaning we have strong links with our sister companies and are able to extend capabilities where required. Our unrivalled product knowledge and 40 years+ experience of delivering class-leading products and engineering expertise has enabled Probe to become the force it is today.