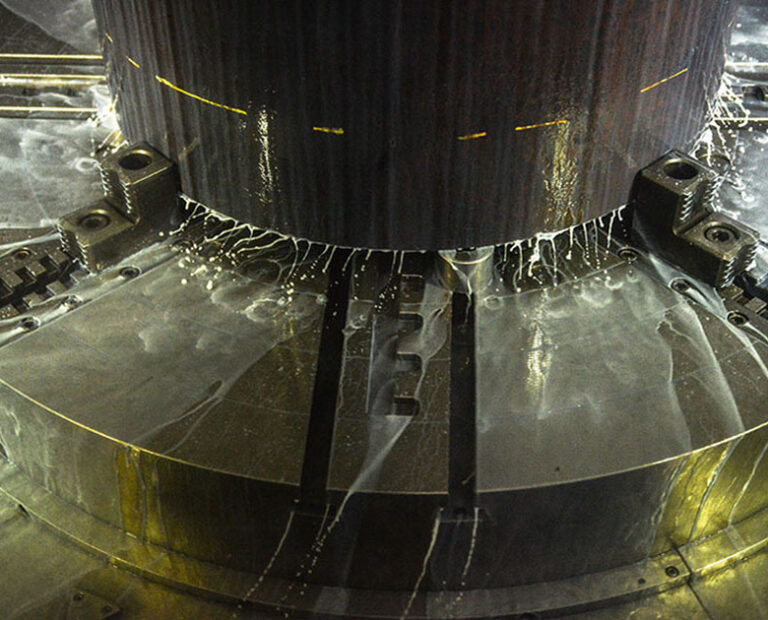

Large diameter refurbishment for riser sections, spools and adaptors. Riser sections up to 50ft in length can be accommodated, which are currently the largest in industry use.

Using a state-of-the-art CNC large machining centre and welding plant, product and service line brand, Probe, can re-face gasket ring grooves and sealing areas as well as apply corrosion resistant overlay to repair damaged areas.

A formal inspection report with refurbishment recommendations is provided on receipt of a product and if refurbishment is not possible, we can manufacture a new product assembly. A refurbishment service is also offered for products which were not originally purchased from us.

Delivered by Probe Oil Tools

For service and supply companies in energy markets, Probe develops and manufactures high quality equipment that optimises asset productivity and performance.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

Similar products and services

-

Lubricator and riser sections are designed for the deployment of wireline, slickline or...

-

Product and service line brand, Probe, are highly experienced in refurbishing and...

-

An extensive range of well intervention equipment to enable well intervention projects to...

-

Riser subs use integral and external gripping profiles to provide a powerful multi-point...